Supply Chain Resilience 2.0: Turning Global Volatility into a Competitive Edge

How Stone3PL Builds “Antifragile” Fulfillment Networks for China’s Global Brands

Introduction

When Red Sea routes close, ports go on strike, and freight costs double overnight, resilience is no longer a CFO’s slide deck concept — it’s a CEO’s survival strategy.

This article outlines a roadmap from resilience to antifragility: using distributed warehousing, predictive data analytics, real-time visibility, multimodal transport, and strategic 3PL partnerships to turn uncertainty into scalable, repeatable, and profitable operations.

Throughout the article, we’ll look at Stone3PL’s South China network and cross-border delivery lines as a plug-and-play model for overseas brands.

1. From Fragile Chains to Elastic Networks

- Multi-node warehousing:

Stone3PL operates three core hubs and eight satellite warehousesacross South China, enabling nationwide pickup within 24 hoursand Southeast Asia delivery within 72 hours. - Flexible capacity over rigid leases:

By pre-booking 30% elastic space before peak seasons and paying per pallet during off-season, clients save up to 18% in warehousing costs. - Dynamic routing vs. linear transport:

The system compares ocean, rail, air, and parcel linesin real time, scoring each by cost, time, and riskto recommend the optimal route in one second.

Result: When port congestion hit, 40% of the volume automatically switched to a rail-plus-satellite model — SLA improved instead of dropping.

2. Predictive Loading Powered by Data

- SKU performance profiling:

Each SKU is scored across 12-week sales, margin, and damage rate, then categorized into A+/A/B/C tiers. - Safety stock and aging thresholds:

A+ SKUs maintain 7 days of safety stock; C-tier hold 21 days. When thresholds are reached, the system auto-triggers clearance or reallocation. - Peak pre-positioning:

Four weeks before Prime Day, predicted A+ SKUs are moved to overseas warehouses. Inventory turnover time drops from 45 days to 19, freeing USD 2 millionin cash flow.

Toolkit:

The Stone3PL WMS + BI dashboard lets clients export “Replenishment Recommendation Sheets” — directly usable for factory production planning.

3. Real-Time Visibility: From Black Box to Glass Box

- Control tower overview:

Shipping rates, space booking, domestic trucking, warehouse handling, and last-mile delivery data are fully API-linked under a single tracking ID. - Condition monitoring:

Sensors track temperature, humidity, vibration, and tilt. Alerts are pushed within 30 minutesfor any high-value shipment anomaly. - AI-driven exception forecasting:

Models trained on customs strikes, weather data, and freight fluctuations predict delays seven days in advanceand auto-recommend backup routes.

Case study:

When Q4 airfreight prices spiked 38%, the system switched to rail + satellite routing 10 days ahead, cutting costs by 22% while keeping on-time performance at 98%.

4. Strategic 3PL: From “Storage Provider” to “Shared Commitment Partner”

- 10-day onboarding:

With standardized API docs, SKU mapping, and packaging templates, new clients can ship their first order within 10 days. - Surge-ready operations:

During peak seasons, shared labor pools and flexible night shifts handle 3× order spikes — error rate stays below 0.2%without adding fixed staff. - Red-carpet exception handling:

A 24/7 bilingual support teamresolves claims or reshipments within 2 hours, keeping complaint rates at one-third of the industry average.

Client testimonial:

“Stone3PL doesn’t just store our goods — they share our SLA. If anything is late, damaged, or mis-shipped, they compensate instantly. We’re confident enough to list their support number on our website.”

— VP of Operations, North American DTC Electronics Brand

5. Next Step: From Resilient to Antifragile

- Machine learning that self-improves:

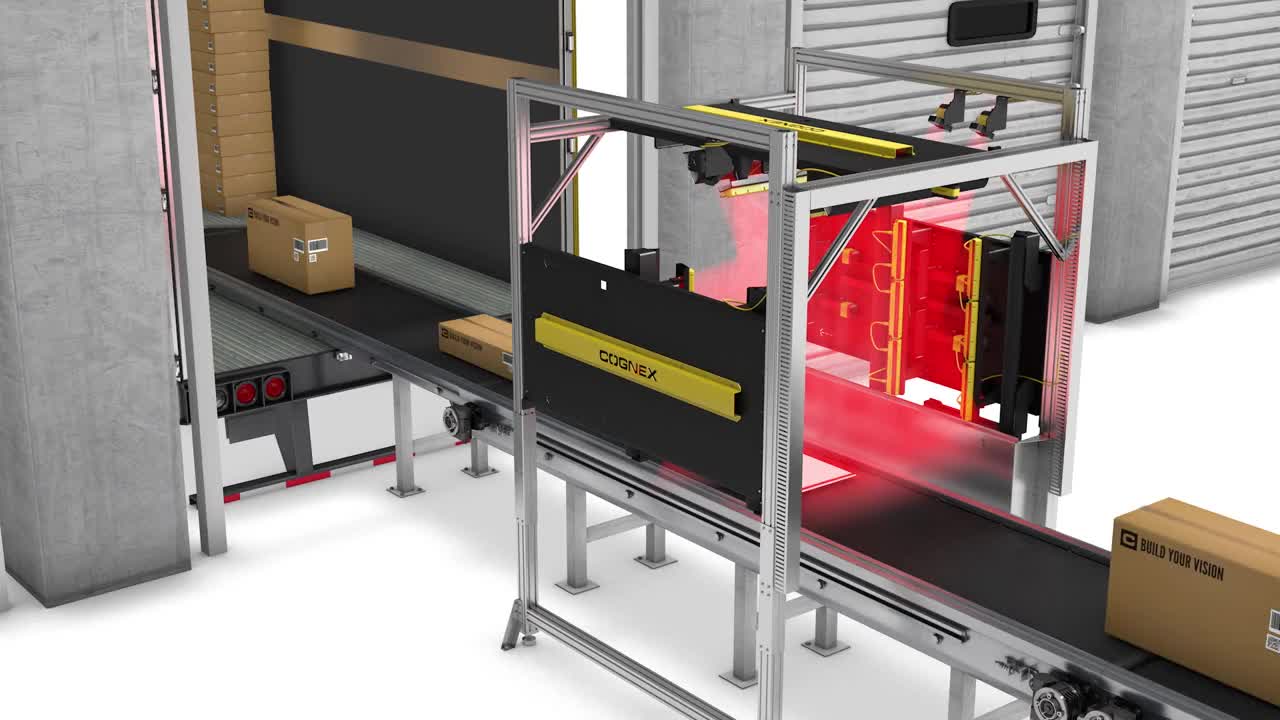

Every delay or reroute becomes new training data. The model retrains weekly, refining network layout recommendations with each cycle. - Automation to shorten lead times:

Automated labeling, sorting, and weighing cut outbound time from 180 minutes to 35 minutes. - Collaborative ecosystem:

3PLs, sellers, factories, and financial partners share one digital twindataset. Inventory, production, and cash flow are optimized on the same timeline — risks are balanced across the entire ecosystem.

Goal:

Not just to “survive” the next Red Sea crisis — but to use the experience to reduce average shipping costs by another 5%, becoming stronger with every disruption.

Conclusion: Turn Risk into OKRs, and Delivery into Brand Value

Global logistics uncertainty will never disappear — but through distributed warehousing, data forecasting, real-time visibility, multimodal logistics, and strategic 3PL partnerships, brands can transform volatility into measurable, repeatable, and compounding operational strength.

Stone3PL has opened this framework to all Chinese global brands:

- Start with data-led inventory management.

- Expand through South China’s flexible warehouse network.

- Learn how to go live in 10 days and co-own SLA performance 24/7 with Stone3PL’s operating model.

Put “supply chain resilience” into your next OKR — and let every black swan event become a 48-hour advantage over your competitors.